|

General Optics

|

本文のエリアです。

Lens Manufacturing

Manufacturing Flow

Manufacturing flow (Factory tour) for Lens

|

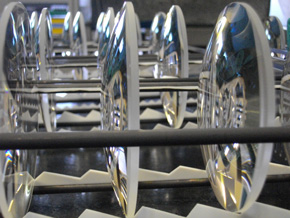

1.Polishing Shine the surface to a mirror-like finish to the radius of curvature as per the drawing. |

|

|

|

|

|

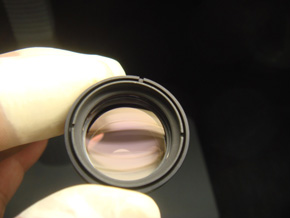

2.Centering Grinding the lens edge to find shape of the lens. |

|

|

|

|

|

3.Coating (Optical thin-film) Antireflection, increased amount of transmitted light, the surface protection is intended, and subjected to a thin film of metal to enhance the ability of the lens itself. |

|

|

|

|

|

4.Cementing By the adhesive cured in UV, is the step of laminating a plurality of optical components (lenses). |

|

|

|

|

|

5.Painting The step of applying the paint for the anti-reflection on the lens edge. |

|

|

|

|

6.Lens assembly

This is a process that setting the finished lens in the lens barrel of metal parts.

By this combination, it will be easy handling to achieve the required optical performance.

Quality Assurance

|

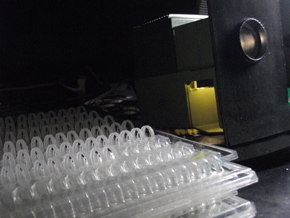

1.Cleaning By the ultrasonic cleaning machine, it is a process that remove the dirt on the lens surface. |

|

|

|

|

2.Quality inspection

After dropping the dirt between every each steps, we will inspect the product in each step whether these has been properly made within the scope of the standard.

Analysis of surface accuracy after polishing. Eccentricity measure after Centering. Confirm the color, wavelength and durability after the coating.

|

Visual intermediate inspection |

Analysis confirmation of surface accuracy |

|

Eccentricity measurement |

Spectroscopic Check |

|

|

|

Final inspection (before shipment) and, packing

Capabilities

| Processing Quantity | For lens Processing quantity |

|---|---|

| Grinding | 50,000pcs per month |

| Polishing | 150,000pcs per month |

| Centering | 800,000pcs per month |

| Coating | 1,200,000pcs per month |

| Cementing / Painting | 30,000pcs per month |

Facility details

Manufacturing Facility

| Manufacturing Facility | Manufacturer | Number of Unit |

|---|---|---|

| Spherical Grinding Machine (manual) | KOSHIN SEIMITSU | 6 |

| Pelleting Machine (semi-automatic) | KOSHIN SEIMITSU | 13 |

| Spherical polishing machine (semi-automatic) |

KOSHIN SEIMITSU | 12 |

| CNC Polishing Machine | KOJIMA ENGINEERING | 2 |

| Plane Grinding Machine 12B / 20B | TAMUKAI SEISAKUSHO | 1 |

| Plane Polishing Machine 12B / 20B | TAMUKAI SEISAKUSHO | 1 |

| Centering Machine (full-automatic) | SHONAN / TATENO | 20 |

| Centering Machine (manual) | SHONAN / TATENO | 23 |

| Single-layer Anti-reflection Automatic Optical Thin Film Coater 800φ |

SHOWA | 2 |

| Anti-reflection Optical Thin Film Coater 800φ |

SHINCRON | 4 |

| Anti-reflection Optical Thin Film Coater 1000φ |

SHINCRON | 2 |

| Multilayer Optical Thin Film Coater 1000φ |

KAWAI OPTICS | 2 |

| Multilayer Optical Thin Film Coater 1100φ (with Ion Source) |

SHINCRON | 1 |

| Multilayer Optical Thin Film Coater 1300φ |

OPTORUN | 2 |

| Multilayer Optical Thin Film Coater 1300φ (with Ion Source) |

OPTORUN | 2 |

| Ultrasonic Washing Machine 9 tanks type (manual) - For polishing, centering |

OKABE SEISAKUSYO | 1 |

| Ultrasonic Washing Machine 12 tanks type (automatic) - For centering |

SONIC FELLOW | 1 |

| Ultrasonic Washing Machine 16 tanks type (automatic) - For coating |

SONIC FELLOW | 1 |

| Ultrasonic Washing Machine 11 tanks type (automatic) - For coating |

SONIC FELLOW | 1 |

| Ultrasonic Washing Machine 13 tanks type (automatic) - For coating |

SONIC FELLOW | 1 |

| Ultrasonic Washing Machine 8 tanks type (manual) - For coating |

SUN CORPORATION | 1 |

| Vacuum packing equipment | 2 | |

| Lathe – For creating tools, correction | 2 |

Inspection Equipment

| Inspection Equipment | Manufacturer | Number of Unit |

|---|---|---|

| Laser interferometer analyzer (with software for RSI measurement) |

OLYMPUS | 3 |

| Laser interferometer analyzer | AKION | 1 |

| Transmission type eccentricity measurement device |

PEARL | 4 |

| Reflective eccentricity measurement device |

OLYMPUS | 1 |

| High precision double-sidedreflective eccentricity measurement device |

SCHNEIDER | 1 |

| Spectrophotometer | HITACHI | 3 |

| Spectrophotometer | NIHON BUNKO | 1 |

| Spectrophotometer | OLYMPUS | 1 |

| CCD microscope | SCHOTT MORITEX | 1 |

| Stereomicroscope | OLYMPUS | 1 |

| Stereomicroscope | CARTON | 1 |

| Toolmaker's Microscope | MITSUTOYO | 1 |

| Temperature and Humidity Control equipment |

1 | |

| Visual inspection for fluorescent lamp 27W |

20 | |

| Visual inspection for cabin slide 150W |

20 | |

| Edge thickness measuring instrument | 1 |