Manufacturing Flow

Manufacturing flow (Factory tour) for Lens

|

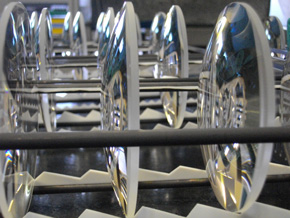

1.Polishing Shine the surface to a mirror-like finish to the radius of curvature as per the drawing. |

|

|

|

|

|

2.Centering Grinding the lens edge to find shape of the lens. |

|

|

|

|

|

3.Coating (Optical thin-film) Antireflection, increased amount of transmitted light, the surface protection is intended, and subjected to a thin film of metal to enhance the ability of the lens itself. |

|

|

|

|

|

4.Cementing By the adhesive cured in UV, is the step of laminating a plurality of optical components (lenses). |

|

|

|

|

|

5.Painting The step of applying the paint for the anti-reflection on the lens edge. |

|

|

|

|

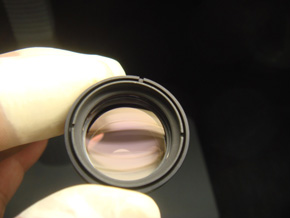

6.Lens assembly

This is a process that setting the finished lens in the lens barrel of metal parts.

By this combination, it will be easy handling to achieve the required optical performance.

Quality Assurance

|

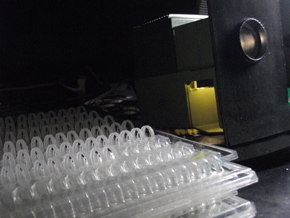

1.Cleaning By the ultrasonic cleaning machine, it is a process that remove the dirt on the lens surface. |

|

|

|

|

2.Quality inspection

After dropping the dirt between every each steps, we will inspect the product in each step whether these has been properly made within the scope of the standard.

Analysis of surface accuracy after polishing. Eccentricity measure after Centering. Confirm the color, wavelength and durability after the coating.

|

Visual intermediate inspection |

Analysis confirmation of surface accuracy |

|

Eccentricity measurement |

Spectroscopic Check |

|

|

|

Final inspection (before shipment) and, packing